Periodic Electrical Installation Inspection and Testing

The HSE regard installations which conform to the standards laid down in BS7671 as likely to to achieve conformity with the relevant parts of The Electricity at Work Regulations 1989.

Existing installations may have been designed and installed to conform to the standards set out in earlier editions of the IEE Wiring Regulations. This does not mean that they will fail to achieve conformity with the relevant parts of The Electricity at Work Regulations 1989.

When setting out to inspect and test an electrical installation for the purpose of veryfying that the requirements of BS7671 have been met, we are therefore going some way to ensuring that the requirements of The Electricity at Work Regulations 1989 are being met.

Periodic Inspection Report

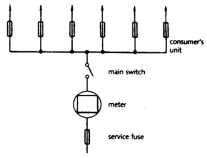

Electrical Installations will deteriorate due to factors such as damage, wear and tear, corrosion, overloading, environmental conditions, etc. With this in mind, legislation requires that electrical installations be maintained in a safe condition.

The Electricity at Work Regulations 1989

Regulation 4 (2) : As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as reasonably practicable, such danger.

Regular inspection of equipment, including the electrical installation, is an essential part of any preventative maintenance programme. The regular inspection may be carried out as required with or without dismantling and supplemented by testing.

Whilst there is no legal requirement to inspect and test, it is in the best interests of all organisations that inspection and testing of electrical installations be maintained up to date in line with the requirements of BS7671. Records of such work should be retained for the lifetime of the system as required by the Memorandum of Guidance to the Electricity at Work Regulations 1989.

There is no specific requirement to test an installation on every periodic inspection. Where testing requires dismantling, the tester must demonstrate that the risks associated with dismantling and re-assembly are justified. For example, it would not be difficult to justify dismantling for the purpose of insulation resistance testing, a relatively new installation that has no indication of deterioration.

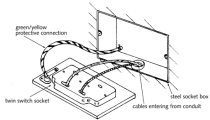

Dismantling, and particulary disconnection of conductors or components introduces a further risk of unsatisfactory re-assembly.